W Beam Crash Barriers: A Closer Look at the Design and Functionality

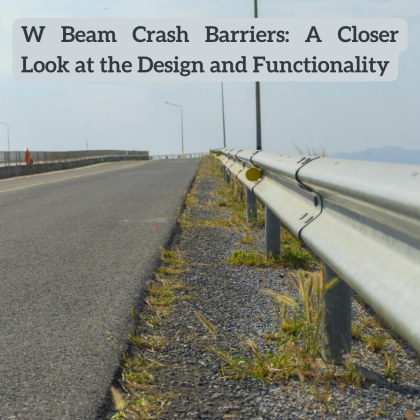

W Beam crash barriers, commonly known as guardrails, are a vital component of road safety infrastructure. These barriers are strategically placed along highways, bridges, and other critical roadways/railways to prevent vehicles from veering off the path, thereby reducing the severity of accidents. In this blog, we take a closer look at the design and functionality of W Beam crash barriers, exploring how they work and why they are essential for safety.

In this blog, we’ll take a closer look at the design and functionality of W Metal Beam Crash Barriers.

Understanding W Beam Crash Barriers:

1. W-Shaped Profile

The most distinctive feature of W Beam crash barriers is their W-shaped profile. This unique design provides the necessary strength and flexibility to absorb and dissipate the energy from a vehicle collision. The shape helps to redirect the vehicle back onto the roadway, minimizing the risk of more severe accidents.

2. High-Quality Materials

W Beam crash barriers are typically made from high-strength galvanized steel. This material is chosen for its durability and resistance to corrosion, ensuring that the barriers remain effective over long periods and in various weather conditions.

3. Posts and Spacing

The W Beam is mounted on steel or wooden posts that are embedded into the ground. The spacing and depth of these posts are carefully calculated to maximize the barrier’s performance. Proper post installation is crucial for the barrier to withstand high-impact collisions.

4. End Terminals

End terminals are an essential part of the W Beam crash barrier system. These components are designed to anchor the ends of the barrier and absorb energy during a crash, reducing the risk of injury to vehicle occupants. There are various types of end terminals, each tailored to specific roadway conditions and crash scenarios.

Functionality of W Beam Crash Barriers

1. Impact Absorption

When a vehicle collides with a W Beam crash barrier, the design allows the barrier to absorb and dissipate the kinetic energy. This reduces the force transferred to the vehicle and its occupants, thereby lowering the likelihood of severe injuries.

2. Vehicle Redirection

The W-shaped design helps to redirect the vehicle back onto the roadway. Instead of allowing the vehicle to break through or go over the barrier, the W Beam guides it along the barrier, gradually bringing it to a stop. This redirection is crucial in preventing secondary collisions and further road hazards.

3. Preventing Roadway Departure

One of the primary functions of W Beam crash barriers is to prevent vehicles from leaving the roadway. By acting as a physical barrier, they protect drivers from potentially dangerous off-road conditions such as cliffs, slopes, or oncoming traffic from the opposite direction.

4. Reducing Crash Severity

By absorbing impact and redirecting vehicles, W Beam crash barriers significantly reduce the severity of crashes. They prevent vehicles from hitting rigid objects or entering hazardous areas, which can result in catastrophic outcomes.

Advantages of W Beam Crash Barriers:

1. Versatility

W Beam crash barriers can be used in a variety of settings, including highways, bridges, medians, and rural roads. Their versatility makes them an ideal choice for diverse road safety applications.

2. Cost-Effectiveness

Compared to other types of barriers, W Beam crash barriers offer a cost-effective solution for road safety. Their relatively low installation and maintenance costs make them a preferred choice for many transportation authorities.

3. Durability

Made from high-quality galvanized steel, W Beam crash barriers are designed to withstand harsh environmental conditions and remain functional for extended periods. Their durability ensures long-term safety benefits.

4. Ease of Installation

W Beam crash barriers are relatively easy to install, requiring standard construction equipment and techniques. This ease of installation contributes to their widespread use in road safety projects.

Conclusion:

W Beam crash barriers are a critical element of road safety infrastructure, designed to protect drivers and passengers by absorbing impact, redirecting vehicles, and preventing roadway departures. Their unique W-shaped design, high-quality materials, and strategic functionality make them indispensable in reducing the severity of road accidents. By understanding the design and functionality of these barriers, we can appreciate their role in enhancing road safety and saving lives.

How to Choose the Optimal Crash Barriers?

When considering the best crash barrier for your needs, it’s crucial to factor in the following considerations:

- Installation Requirements: Assess the installation process to ensure compatibility with the intended location and feasibility of implementation.

- Flexibility of the Chosen Barrier: Evaluate the barrier’s flexibility to determine its ability to absorb impact and minimize damage during collisions.

- Barrier Terminal Treatment: Consider the terminal treatment options available to ensure proper end protection and seamless integration with the roadway.

- Required Length: Determine the necessary length of the barrier to adequately cover the designated area and provide comprehensive protection.

- Transition Between Barrier Types: Assess the transition between different types of barriers, if applicable, to ensure smooth continuity and optimal safety measures.

By considering these factors and ensuring compliance with international specifications, you can confidently select crash barriers that offer optimal performance and safety for your specific requirements. Adherence to the standards guarantees that the barriers are manufactured using high-grade raw materials, ensuring superior strength and stability.

Looking For High Quality W Metal Beam Crash Barrier Manufacturer In India?

Explore our Metal Beam Crash Barrier. We manufacture metal beam crash barriers that meet American (AASHTO M180), European (EN 1317-1 & 2), and Indian Road Congress (IRC) standards. We provide comprehensive solutions that include both single and double-sided w beam crash barriers.